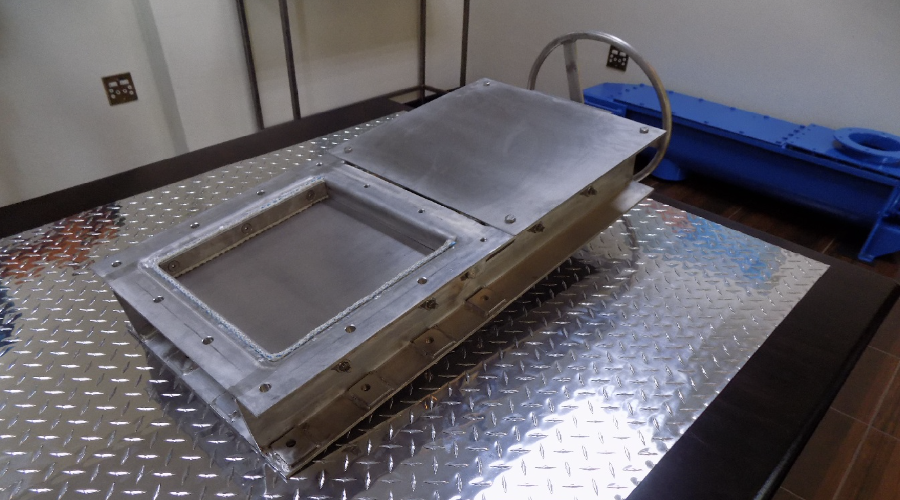

The standard knife gates are constructed from a rigid mild steel channel frame or on request from other material. The gate plate is made from 3CR12 to ensure a smooth and corrosion resistant surface. The gate plate is supported by replaceable stainless-steel guides. Other gate plate materials are available on request. The gate plate is actuated by a spindle (brass) and spindle nut (cast iron) attached to the gate plate. The spindle is supported by a specially machined mild steel bearing block housing the self-aligned seal ball bearing. A special inlet sealing arrangement together with the stuffing box type seal where the gate plate passes through the frame is standard. To protect the spindle from being damaged a cover plate is provided.

The knife gates are designed for horizontal installation only and the spindle cover plate must be on top of the spindle. Certain applications required the knife gate to be operating in slanting positions (i.e. Diverter chutes etc…). In this case it is important to install the gate with the stuffing box on the high side of the chute outlets away from the material flow. The connecting flanges must be of adequate thickness as well as flat and level in all direction. The tightening of the bolts should be done in the following sequence: Right corner -diagonal opposite corner; left corner – diagonal opposite corner; right inside – directly opposite; left inside – directly opposite and so on to a hand tight setting of all bolts. The final tightening should be done in the same sequence. Thick, soft rubber gaskets should be avoided as these encourage the unequal tightening of bolts and can lead to distorting the knife gates and thus impairing the proper functioning thereof. All sizes of knife gates have tapped bolt holes in the flanges on the stuffing box side for ease of installation. It must be made sure that the correct length of bolt is used. (Thickness of spring washer & site connecting flange & gasket & bolt diameter = bolt length)

The operation of the knife gate is either manually (handle, handwheel or chainwheel) or automatically (electric gearmotor or pneumatic actuator).

Knife gates take only little effort to open and close the gate plate.

If this is not so, then something is not normal, and the knife gate should under no circumstances be forced with levers etc to prevent serious damage.

Since knife gates have sealing elements these must be checked and adjusted frequently to prevent leakage. In case of stuffing box type seals, a replacement of the complete packing becomes necessary when the full adjustment of the gland is taken up.

It is not satisfactory to add just another packing strip behind the old ones. Frequently check for wear and loose bolts

Manual operation

Spindle should be checked regularly for lubrication. Recommended lubricant: High Grade Lithium base grease as Valvoline Val-Lith EP Multi-Purpose grease or equivalent.

Motorized operation

Spindle as in a). Geared motor refers to separate chart