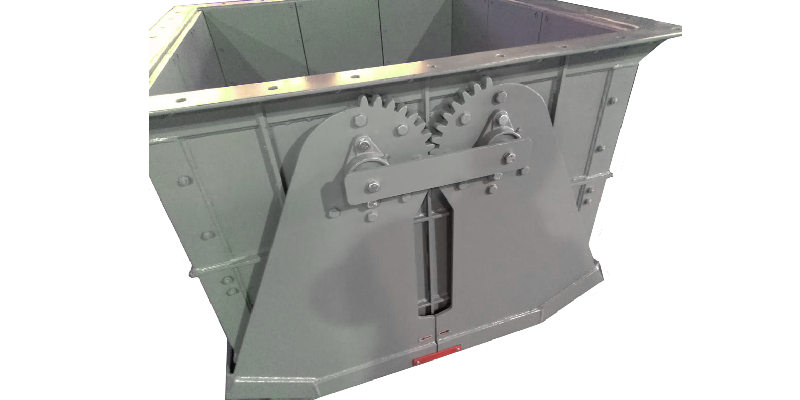

The clam shell gates are manufactured in mild steel with a Roqlast or Bennox chute. The chute is enclosed by a shell which consists of left- and right-hand side. The left a right-hand side of the shell are connected by a link which ensure that they open simultaneously. The series ‘CS’ clamshell gates are designed and manufactured locally as discharge units for dry bulk material from bins and hopper

Installation

The clam shell gates are intended for a vertical installation only. Before bolting the clam shell gate to the connecting flange, it must be made sure the these are of adequate thickness as well as flat and level in all directions to ensure a proper, distortion free and sealed connection.

Furthermore, the tightening of the bolts should be done in the following sequence. Right corner – diagonally opposite corner; left corner – diagonal opposite corner; right inside – directly opposite; left inside – directly opposite and so on to a hand tight setting of all bolts. Then the final tightening should only be done in the same sequence. Thick, soft rubber gasket should be avoided as these encourage the unequal tightening of bolts and can lead to distortion.

These units as ALL our products are tested and witnessed by customer/Quality inspector.

The clam shell gates are either hand or pneumatically operated.

All bearings leave our factory packed with enough grease and should be checked on regular basis and only lubricated periodically depending on operating conditions.